Research Projects

AME 2.0 - New development of a 3D printer for quality-optimized additive manufacturing of rubber-based moulded parts

| Led by: | M. Sc. Sebastian Leineweber |

| E-Mail: | sebastian.leineweber@ita.uni-hannover.de |

| Year: | 2024 |

| Funding: | German Aerospace Center (DLR) |

| Duration: | 01.04.2024 - 31.03.2026 |

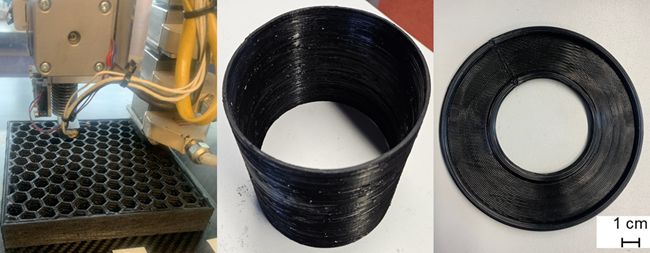

Like its previous project Elastomer-3D, this project is being carried out jointly with German Institute of Rubber Technology (DIK). While DIK is concentrating on material development and characterization, as well as material testing of printed components, ITA is responsible for developing of an optimized new AME-3D-printer. In particular, printing resolution of components is to be improved by using a more powerful extruder, making it comparable to conventional fused-filament-fabrication- (FFF)-3D-printers. There is also a change in the movement. Unlike its previous model, movement in the three dimensinal directions takes place via a movable printing table and is no longer realized via a movable printing unit. This is advantageous as significantly less weight has to be moved. ITA is also responsible for developing a simulation tool that determines the vulcanization time specifically for each component and rubber compound. It is essential to know vulcanization duration before actual vulcanization, especially for manufacturing individual parts such as prototypes and spare parts, to avoid having to manufacture several components as a result of incorrect vulcanization. Once the 3D-printer has been launched, various industrial components such as damping elements, seals and membranes will be printed and tested by companies from the project committee. The companies' industrial and component-specific test benches will be used to evaluate this manufacturing process.